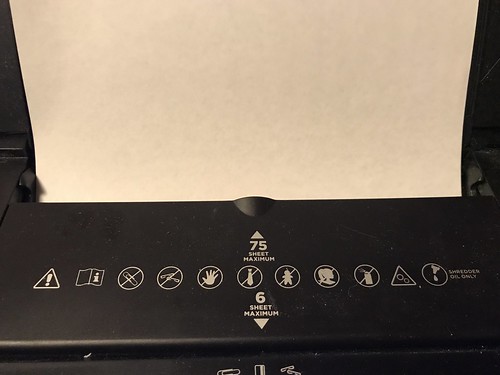

This model has two slots: the regular intake slot labelled "6 SHEET MAXIMUM" and the auto-feed slot labeled "75 SHEET MAXIMUM". I am in the process of destroying this shredder - which was brand new just a few days ago - or at least certainly violating its warranty, by exceeding its duty cycle: over the span of a couple of weeks, I'll be reducing several decades of financial paperwork to tiny bits of paper.

It occurred to me, as I spend hours feeding paper into this device, stopping occasionally to let it cool down, clearing jams, lubricating it, and cleaning some components using a procedure for sure not covered in the owner manual, that some folks might not know the real meaning of those "SHEET MAXIMUM" notations. As a professional product developer with more than four decades of experience, let me enlighten you.

Decades ago I worked at a national lab in Boulder Colorado. My boss, who had a Ph.D. in physics, used to say that any claims a supercomputer manufacturer made for the ginormous systems they sold were in effect guarantees that those systems could under no circumstances exceed those specifications. It didn't matter whether they were for instructions per second, floating point operations per second, disk I/Os per second, and so forth.

In the fullness of time, I, as a product developer, came to understand this was much more broadly applicable than just supercomputers. Applicable to both the devices I was trying to use in the products I was helping my clients develop and ship, and to those products themselves. In this latter capacity, I may have played a role in determining a product specification or two. It is even possible you have used some of those products.

Let's focus on the auto feed specification for my paper shredder: "75 SHEET MAXIMUM". What does this really mean?

(Disclaimer: what follows is a completely fictional but probably highly accurate portrayal.)

At some point in time, an engineer, who probably had at least a master's degree in mechanical engineering, took one of these shredders and ran some tests on it. It was likely it was a laboratory mule used for prototyping and early firmware development, many months before the first production model came off the assembly line, since such a machine would have already had to have the manufacturing process established to print this label on the unit. This was done in a climate-controlled clean room environment, carefully cleaned and scrubbed, and devoid of any food or drink. The engineer - and indeed everyone in the lab - wore clean-room "bunny" suits, meticulously free of any foreign matter.

The engineer carefully installed brand new hand-sharpened blades; lovingly hand adjusted all the tolerances of all the moving parts, running bearings far more expensive than what would be used in the actual production unit, and carefully lubricated all the parts using the most expensive lubricant from his lab supplies.

The engineer used brand new paper, right out of the box, devoid of any toner, perfectly flat, and as thin as was available commercially, but not too thin. The engineer cleaned the paper with aerosol canned air, fanned the stack of paper out to make sure none of the pages stuck together, and checked that each page was momentarily grounded to eliminate any static electricity.

The engineer carefully started testing the printer, using a pair of calibers and a stainless steel ruler to make sure the stack of paper in the input bin of the shredder was precisely aligned. The engineer tested stack after stack, adding one single page to each test. For each test, the engineer took the temperature of the electric motors in the shredder, making sure they were not overtaxed, allowing the shredder to cool down completely, probably overnight, in between each test. Each morning, the engineer relubricated and realigned all the mechanical bits in the prototype, possibly replacing any parts that showed the most minuscule amounts of wear when viewed under a laboratory microscope costing tens of thousands of dollars.

When the engineer reached seventy-six pages, the shredder exploded. The shrapnel killed everyone in the room. The shredding blades were especially lethal.

The engineer's supervisor, who had an MBA, came into the room, read the final number off the engineer's laboratory notebook, and notified manufacturing what the limit was: seventy-five sheets."75 SHEET MAXIMUM" means seventy-five is the limit under the most optimal, controlled conditions that are humanly possible in the most optimistic of all conceivable circumstances.

In my basement, feeding ancient reports that had been folded, spindled, and mutilated, having sat all that time in a filing cabinet, with no climate control other than the nearby furnace which runs from time to time, reports from which I had just violently removed the staples I had inserted years ago, and having one of our beloved feline overlords supervising my efforts, I find that seven sheets sometimes works. And sometimes not.

That's what a product specification means.

No comments:

Post a Comment